Our goal

The production and use of fossil-based plastic materials has a negative impact on our planet. However, these materials are currently essential for many applications, like foam materials used in shoe soles or construction materials. These products are typically made of polyurethane (PU).

In the past years, the interest in bio-based chemicals and bioplastics has increased. Improving recyclability and reducing the carbon footprint is our goal.

The main challenge in developing bio-based alternatives is balancing environmental, economic, and social benefits. To maximise use and impact, these alternatives must match or outperform the properties of petroleum-based products, while being affordable. PU is used in many everyday products for its elasticity and abrasion resistance (scratch-proof). However, the use of isocyanates in PU production poses significant health and environmental hazards, and recycling PU is nearly impossible, leading to incineration or environmental pollution. It’s crucial to develop Non-Isocyanate PUs (NIPU) from bio-based materials that are easier to recycle.

Our new bio-based chemicals are also interesting for making bio-based polymers, for example (block)coploymers with other bio-based products such as PolyLactic Acid (PLA). Combining PLA with our new bio-based chemicals will result in better mechanical properties and a broader use of these polymers. A bio-based platform chemical contributing to enhanced properties and degradability could thus lead to new uses for the material, boosting its demand and reducing production costs.

The last decade of academic research has shown the unique qualities of 3MdVL and 3MPD as platform chemicals to be used such large scale applications. Now it is time to scale up the production, and use these new bio-based platform chemicals in products that are ready for the future.

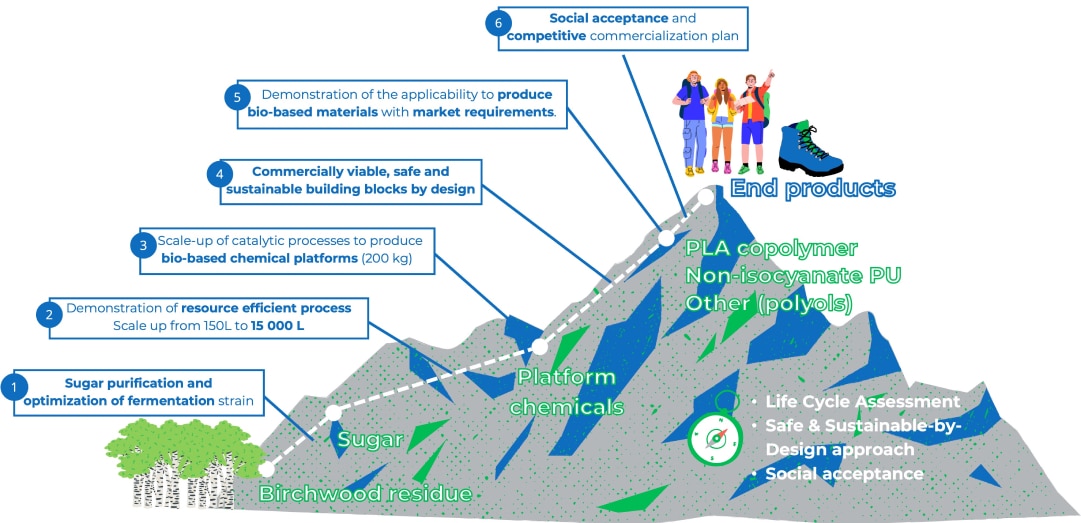

Our journey

We are on a journey to make sustainable, bio-based, recyclable and affordable products starting from wood residues.

The objective of NEXT-STEP is to scale-up and demonstrate a sustainable, resource and energy efficient production route for bio-based aMVL, 3MdVL and 3MPD from second generation feedstock. NEXT-STEP will further demonstrate the applicability of aMVL, 3MdVL and 3MPD as a chemical building blocks for end-products, such as PLA based shoe outsoles, a recyclable NIPU foam for shoe midsoles and for insulation material for construction.

This will be achieved through 6 specific objectives:

- Sourcing and process optimization for EU-based and sustainable feedstocks.

- Scale-up and demonstration of an innovative and resource efficient process to produce aMVL.

- Scale-up resource efficient catalytic processes to unlock the use of 3MdVL and 3MPD as bio-based platform chemicals.

- Commercially viable, safe and sustainable building blocks by design.

- Demonstrate the applicability of aMVL, 3MdVL and 3MPD as bio-based chemical platforms to produce bio-based products meeting market requirements.

- Definition of socially acceptable and competitive business and commercialization plan

Our findings on the way:

become better for People, Planet and Profit

Greener Choices: Bio-based products often contain fewer harmful chemicals compared to their fossil-based counterparts. In NEXT-STEP we will focus on this in every step of the production.

Cost: Biobased products can be more expensive to produce than fossil-based products. However, as technology improves and demand increases, the cost is expected to come down.

Innovation: There is a lot of potential for innovation in the biobased product industry.

In NEXT-STEP scientists and companies work together to

create sustainable alternatives.

Supporting Local Economies: Our biobased products are produced in the EU, which supports local farmers and businesses. This can lead to job creation and a stronger local economy.

Consumer Awareness: As we become more aware of environmental issues, we are more likely to choose products that are less harmful. Together we can make companies produce more sustainable products.

Environmental Benefits: Bio-based products are better for the environment.

They help to reduce pollution and greenhouse gas emissions because they come from renewable resources such as trees.

Reducing Waste: Our bio-based products are designed to be biodegradable and recyclable. This means they break down naturally without harming the environment or can be reused, reducing the amount of waste that ends up in landfills.

Sustainability: Using bio-based products supports sustainable forestry practices. This helps maintain healthy ecosystems and biodiversity.

Our innovations

NEXT-STEP materials can target several high-end products

Bio-based high-performance shoe-soles

Bio-based high-performance insulation

Building blocks for bio-based high-end products

Our supporters – Acknowledgement

The NEXT-STEP project is supported by the Circular Bio-based Europe Joint Undertaking and its members, under GA 101157081